Kohler Engine KD15 440

Kohler diesel engine series KD15 model 440

The Kohler Group, with the release of the new KD15 440 model on the market, has decided to further improve the performance of the famous Lombardini 15LD 440 already market leader in the sector, offering reduced fuel consumption and low emissions levels (for the European market suitable for Stage V standards). The KD15 440 is an air-cooled single cylinder diesel engine with a displacement of 441 cc and a power of 7.4 kW, which thanks to the new air filter and the new tank, is the engine with the longest maintenance intervals and more simple category maintainability. Its remarkable versatility makes it useful for many applications, such as: walk-behind tractor, tiller, lawn mower, water pump (irrigation), concrete mixer, minidumper, compaction roller, vibrating plate, asphalt cutter, line striper, self-priming water pump, air compressor, generator set, welder, motor sweeper, aerial platform, high pressure washer, fire fighting pump.

To view all the other Kohler engines go to Kohler Engines Catalogue

To view the Lombardini engines insteand, go to Lombardini Engines Catalogue

New product

-

In order to meet ever increasing market demands, the kohler group has been updating its range of air-cooled, single cylinder diesel engines. Now, we are pleased to present the new kd15 440 engine, which, with its advanced technical features, strengthens and improves the current 15 ld ngine series elevating it to the very top of the class within its power range.

The 15 ld440 model, already a market leader in numerous sectors including: agriculture, construction, generating sets and pumps, has been substantially updated. Now re-branded as the kd15 440, the new engine has improved performance, reduced maintenance costs and increased ease of use for the operator.

AIR CLEANER. The new air filter allows an use also in extremely dusty conditions. This result has been achieved thanks to a high efficiency separator with pre-filter (optional) and an ccumulated-dust drain valve in the filter itself. Furthermore, the increased dimensions of the cartridge and the high filtration capacity of the paper element greatly enhances the engine protection, resulting in a considerable reduction in maintenance costs.

TANK AND FUEL FILTER. The new tank, with its modified components, greatly contributes to facilitating all maintenance operations due to some significant improvements, including a new fuel filter which is enhanced with additional safety filter protection. The primary filter (optional) and the safety one, used in tandem, avoid the accidental entry of foreign particles during the fuel refilling process. The primary filter housed inside the tank is easily accessible and can be replaced without the use of any special tools.

DRAIN TAP. The new drain tap makes it possible to remove water and impurities which accumulate in the bottom of the tank, allowing for cleaning without the need to dismantle other components.

TAIR CLEANER CLOGGING INDICATOR (OPTIONAL). The air filter clogging indicator integrated into the engine configuration makes it possible to clearly see when maintenance is required.

LARGER OIL SUMP (OPTIONAL) The larger oil sump increases the intervals between maintenance to 500 hours as opposed to 250 hours in standard versions.

MAIN APPLICATIONS

Walk-behind

Tiller

Lawn Mower

Water Pump (Irrigation)

Concrete Mixer

Minidumper

Compaction Roller

Vibrating Plate

Asphalt Cutter

Line Striper

Self-Priming Water Pump

Air Compressor

Generator Set

Welder

Motor Sweeper

Aerial Platform

High Pressure Washer

Fire fighting pump

CUSTOMER BENEFITS

High Power Density

Low Weight

Low Fuel Consumption

Low Oil Consumption

A Complete Range of Accessories

-

4 stroke air cooled diesel engine

Conical power take-off on crankshaft

Anticlockwise rotation

Forced lubrication with oil pump

Centrifugal mass governor

Built-in full flow oil filter

Oil breathing blow-by with safety device

Automatic extra fuel starting device

Self bleeding fuel system

Torque adjuster

Automatic compression release

Die-cast aluminum crankcase with integral cast iron cylinder liner

Aluminum cylinder head

Built-in rigid feetCylinder 1 Bore (mm) 86 Stroke (mm) 76 Engine displ (cm3) 441 Injection system DI Compression ratio 20.3:1

-

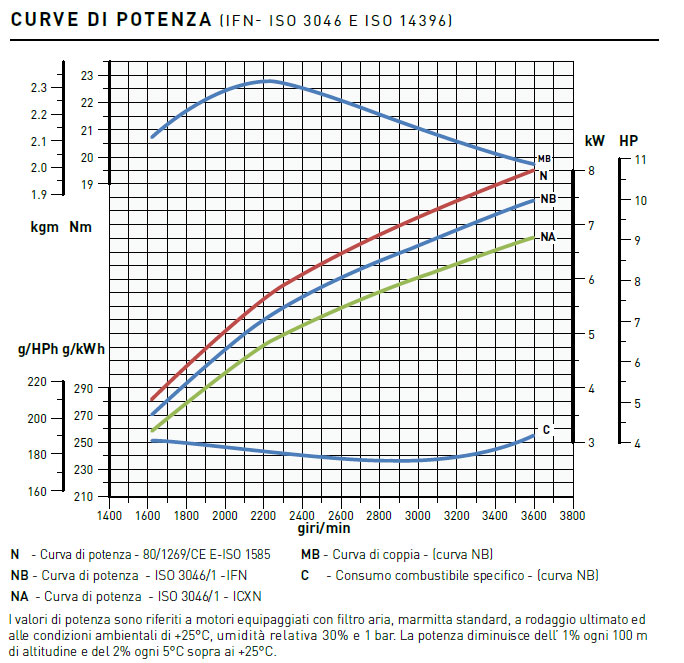

Emission compliance ECE R 24 US TIER 4 F EU Stage V# Rating (kW/HP)*Performance curves 3600rpm 3600rpm 3600rpm N (80/1269/CEE)ISO 1585 - - - NB ISO 3046 IFN 7.5/10.1 7.0/9.4 7.5/10.1 NA ISO 3046 ICXN - - - Max torque (Nm@rpm) 23@2200 23@2200 24.5@2200 Min idling speed 950:1000

-

H × L × W (fan excluded) (mm) 493.1 × 412.8 × 340 Dry weight (kg) 45 Daily service points - positions 1 side service Ambient operating temps (°C) -10° to +50° Gradeability-all round

(intermittent -30 min) (deg)25° Gradeability-all round(

peak value -1 min) (deg)35° Cap. of air required for correct combustion @3600 (l/min) 640 Cap. of air required for correct cooling @3600 (l/min) 5500

-

Fuel tank capacity (l) 4.3 Oil sump capacity (l) 1.2 Oil consumption (kg/h) 0.0032 Oil change interval std/synthetic (hr) 250 Oil filter change interval std/synthetic (hr) 500 Dry air cleaner change interval (hr) 500 Valve adjustement 500 Lubrication SAE 5W 40 API Service CF