Lombardini engine 9LD 625/2

Lombardini diesel engine 9 LD 625/2

Lombardini engine 9LD 625/2, 25.5 cv air-cooled 2 cylinders. These motors represent the best market proposal for their own segment, delivering durable performance, compactness and low maintenance costs. Much used in applications such as 4x4 tractors, pumps and compressors, generating sets, farm machinery, mini dumpers.

New product

-

4 stroke air cooled diesel engine

Direct injection

Mechanical fuel lift pump

Forced lubrication with oil pump

Full flow oil filtration

Torque regulator

Centrifugal speed governor

Crankcase in die-cast aluminum

Electric starting

Counter-clockwise rotation (from power take-off side)

Aluminum alloy independent heads

Indipendent cast iron cylinders

Automatic extra fuel starting device

Air cooled by fan

Power take-off on FlywheelCylinders 2 Bore (mm) 95 Stroke (mm) 88 Engine displ (cm3) 1248 Injection system DI Compression ratio 17.5:1

-

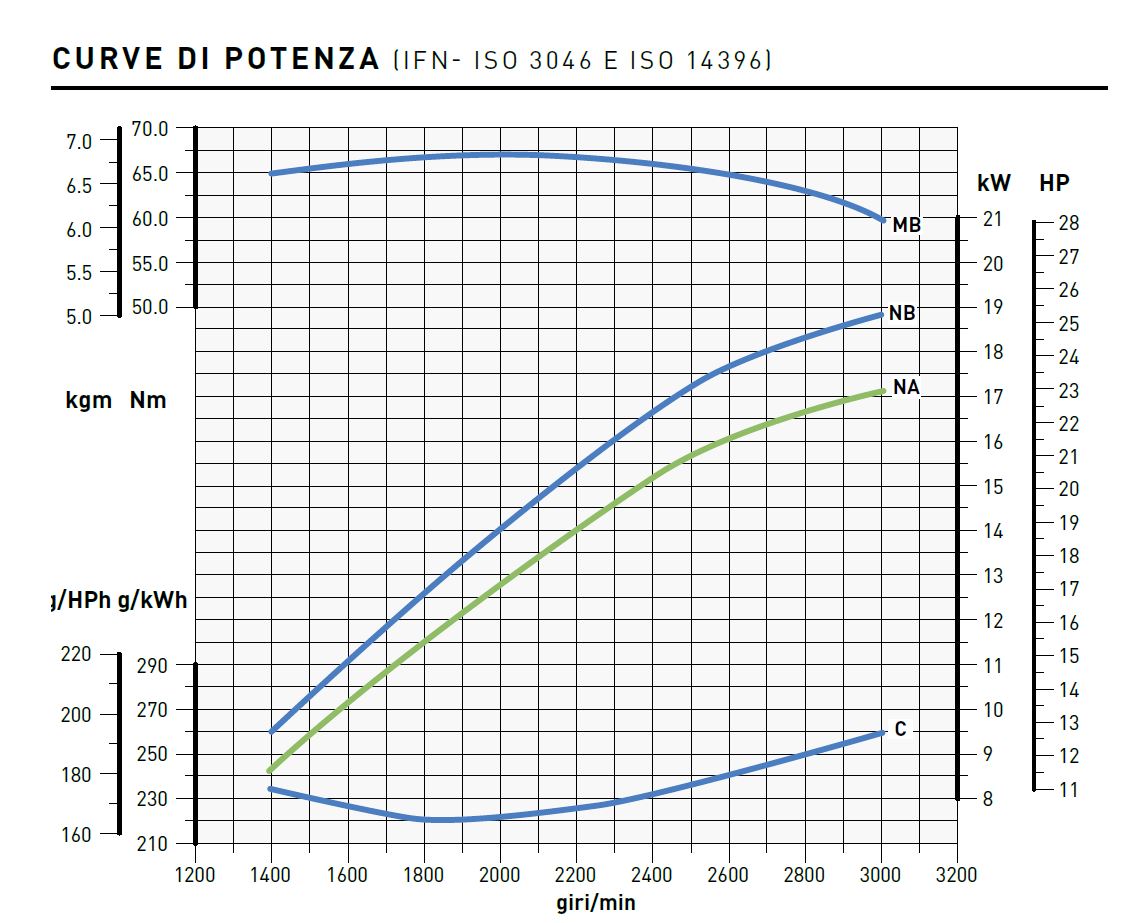

Emission compliance ECE R 24 EPA TIER 4 Rating (kW/HP)*Performance curves N (80/1269/CEE)ISO 1585 - -- NB ISO 3046 IFN 18.8/25.5 16.5/22.4 NA ISO 3046 ICXN 16.9/23.0 15.0/20.4 Max torque (Nm@rpm) 67.0@2000 52.5@3000 Min idling speed 1000 ÷1100

-

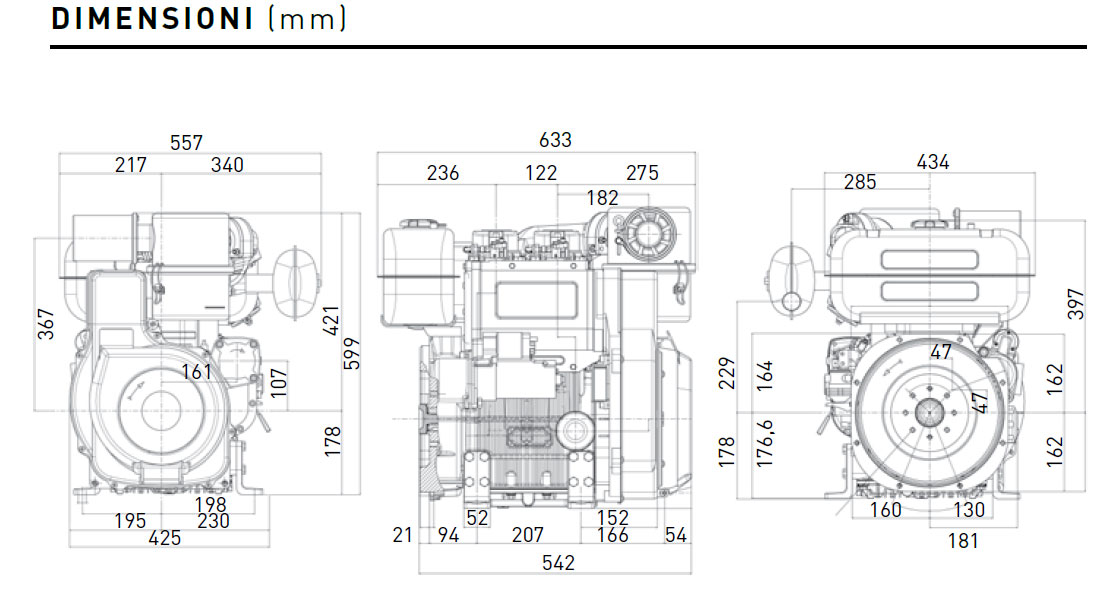

H × L × W (fan excluded) (mm) 599x633x557 Dry weight (kg) 115 Daily service points - positions 1 side service Ambient operating temps (°C) -10° +45° Gradeability-all round

(intermittent -30 min) (deg)25° Gradeability-all round

(peak value -1 min) (deg)35° Cap. of air required for correct combustion @3600 (l/min) 1600(@3000) Cap. of air required for correct cooling @3600 (l/min) 26300 (@3000)

-

Fuel tank capacity (l) 10 Oil sump capacity (l) 2.8 Oil consumption (kg/h) 0.013 Oil change interval std/synthetic (hr) 250 Oil filter change interval std/synthetic (hr) 250 Dry air cleaner change interval (hr) 250 Valve adjustement (hr) 250 Lubrication Oil SAE 10W 40 API CF4/SG

ACEA B2/E2

-

Freq. rpm Engine model Mechanical power Stand-by electric power Prime electric power Flanges Stand-by KW-HP Prime KW-HP Kva kw kva kw cono ø 50 Hz 1500 9LD 652/2 10. - 14.6 9.85 - 13.3 11.4 9.1 10.4 8.3 SAE 4 -7,5 50 Hz 3000 9LD 652/2 18.8 - 25.5 17.1 - 23.2 20.3 16.3 18.8 15 STD LOMBARDINI 60 Hz 1800 9LD 652/2 13.0 - 18.5 12.3 - 16.7 14.4 11.5 12.8 10.3 SAE 4 -7,5